News

In 2020, it was rated as a national specialized and new "little giant" enterprise by the Ministry of industry and information technology

2022-12-12 466

EVA resin (ethylene vinyl acetate copolymer) has high transparency and high adhesion, and is suitable for various interfaces such as glass and metal. Excellent resistant to high temperature, low temperature, ultraviolet light and moisture. EVA resin in China is mainly used in photovoltaic adhesive film, foaming material, cable material, coating, hot melt adhesive and agricultural film.

With the development of China's photovoltaic industry, precoating technology and halogen-free flame-retardant cable, photovoltaic adhesive film, coating, wire and cable have become an important downstream of EVA resin. In the process of China's industrial upgrading in the future, the demand for high-end EVA resin products used in emerging technology applications such as photovoltaic packaging adhesive film, film, precoating film and cable production will further increase.

Photovoltaic adhesive film is an important packaging material for photovoltaic modules, which is used to produce photovoltaic modules and protect the batteries inside the modules.

According to different product structures, it can be divided into EVA film (ordinary transparent EVA film, white EVA film), POE film, etc. EVA is mainly used for single glass photovoltaic cells, POE adhesive film is mainly used for double glass photovoltaic glass, and the technical route of adhesive film is relatively stable.

China's EVA imports are highly dependent, and there is a large space for import substitution in the future. In 2017-2020, China's EVA plants will have no new capacity. In 2021, new plants of Yuneng Chemical, Yangzi Petrochemical and Sinochem Quanzhou will be put into production. The domestic capacity will increase to 1.472 million tons, the output will be 1 million tons, the apparent consumption will be 2.05 million tons, the import will be 1.117 million tons, and the import dependency will remain 54.2%.

Hindered phenolic antioxidants can effectively inhibit or reduce the oxidation reaction rate of plastic macromolecules, prevent or inhibit chain initiation reaction and chain growth reaction by capturing peroxy free radicals, so as to terminate free radical chain reaction, achieve the purpose of preventing oxidation and prolong the service life of plastic products.

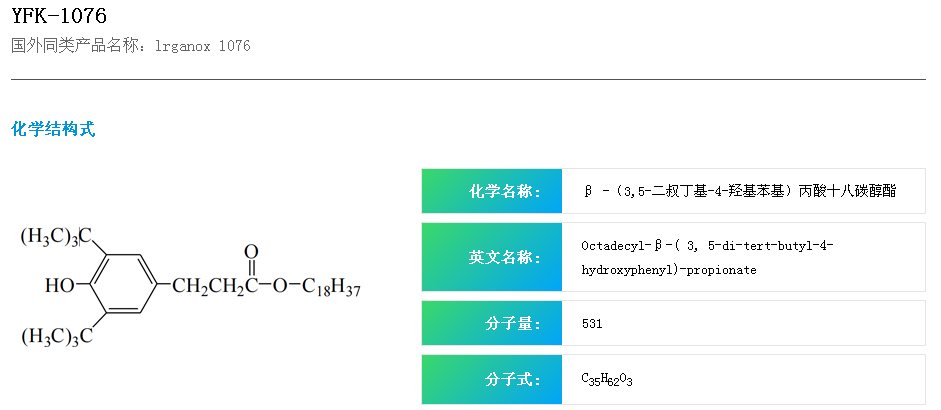

YFK-1076 is the first hindered phenolic antioxidant in EVA. It has excellent effect when used in EVA resin and has good compatibility with EVA resin.

Fengguang YFK-1076 can improve the high-temperature processing stability of EVA resin and significantly improve the anti-aging performance of EVA resin. After the accelerated aging test, the mechanical strength and elongation at break of EVA resin have significant advantages over the control sample. The melt index of EVA resin added with YFK-1076 had little change after five times of continuous extrusion in a single screw extruder, and the oxidation induction period was prolonged by differential thermal analysis (DTA). At the same time, YFK-1076 has excellent anti precipitation performance, good compatibility with EVA resin, and low toxicity and environment-friendly characteristics.

Previous:

Next:

Copyright: Yingkou Fengguang Advanced Material Co., Ltd.Liao ICP Filing No. 17015501-1 Technical Support:![]() onnuoIAD

onnuoIAD

© COPRIGHT 2021 FENGGUANG ADVANED MATERAL.ALL RIGHTS RESERVED